The Development of In-Mold Decorations in Production Processes

The Development of In-Mold Decorations in Production Processes

Blog Article

Understanding In-Mold Decorations: Techniques, Patterns, and Ideal Practices for Ideal Outcomes

In the realm of production, the art of in-mold decorations stands as a crucial facet of product layout and production. In-Mold Decorations. By diving into the approaches, patterns, and ideal techniques that underpin successful in-mold decoration processes, businesses can unlock a realm of possibilities that not just elevate the aesthetic allure of their items but likewise streamline production effectiveness and boost customer engagement.

Product Choice

Product option is a critical facet of mastering in-mold decors, as it directly impacts the quality and toughness of the final item. When selecting materials for in-mold designs, it is important to think about elements such as compatibility with the molding procedure, the wanted aesthetic outcome, and the ecological conditions the product will certainly deal with.

In addition, the chosen material should have great adhesion residential properties to make certain that the design sticks firmly to the substrate during the molding process. Bond in between the material and the decoration is vital for avoiding delamination and making certain resilient aesthetic allure. Furthermore, products with high warmth resistance are preferred for in-mold designs, specifically for products that will certainly be subjected to raised temperature levels during their lifecycle. By very carefully choosing the suitable product for in-mold decors, manufacturers can boost the overall quality and resilience of their items, fulfilling the expectations of both end-users and clients.

Style Technology

A crucial variable in progressing the field of in-mold decorations is the constant exploration and execution of layout innovation methods. Style innovation plays a critical duty in enhancing the visual appeal, functionality, and total top quality of items made utilizing in-mold decoration processes. By incorporating innovative layout aspects, producers can distinguish their products out there, draw in consumers, and stay in advance of competitors.

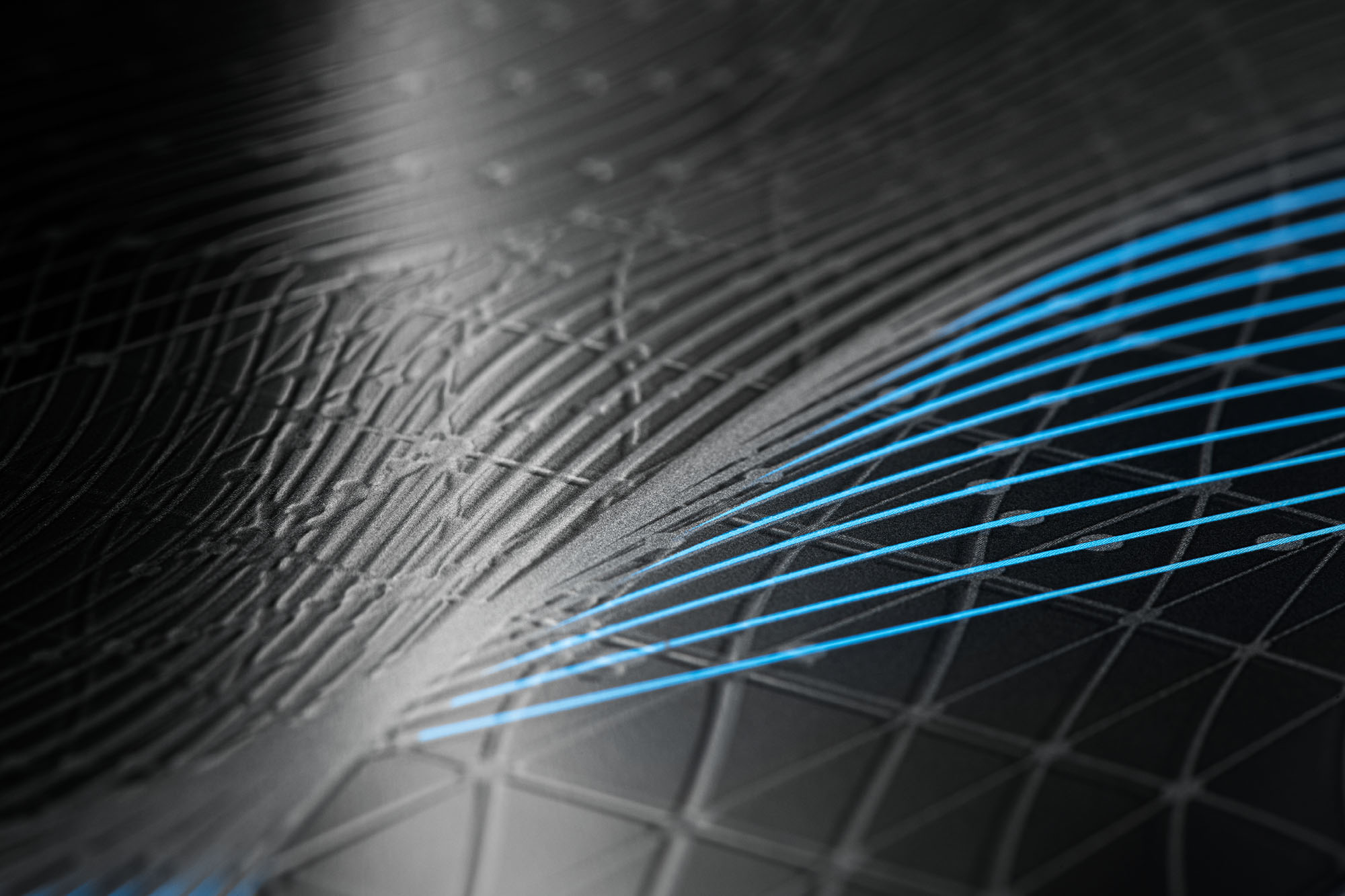

One of the vital facets of design innovation in in-mold decorations is the assimilation of intricate patterns, structures, and graphics that were formerly testing to accomplish with typical decor techniques. Advanced technologies such as 3D printing and electronic style devices enable designers to produce complex and detailed layouts that can be perfectly transferred onto shaped parts. In addition, making use of vibrant shades, metal coatings, and special effects like gloss or matte textures can even more elevate the visual appeal of in-mold enhanced items.

Moreover, layout innovation prolongs past appearances to incorporate useful improvements such as ergonomic forms, integrated features, and personalized components that deal with details customer needs. By welcoming style innovation, producers can unlock brand-new possibilities for imagination, product, and customization distinction in the competitive landscape of in-mold decors.

Production Efficiency

Efficient manufacturing processes are necessary for translating the innovative layouts developed in the field of in-mold decorations into premium completed items that fulfill market demands and consumer assumptions. In the world of in-mold Discover More designs, manufacturing efficiency incorporates numerous key elements that add to the total success of the manufacturing procedure. One vital component is the optimization of mold design and tooling to make sure specific and smooth design transfer onto the end product. By fine-tuning mold configurations and buying top quality tooling materials, producers can boost effectiveness and consistency in manufacturing.

Automation not only accelerates the production process however additionally enhances precision and repeatability, leading to a more uniform and high-grade end product. On the whole, an this article all natural approach to production effectiveness is extremely important in making the most of the possibility of in-mold decoration strategies and attaining optimum results in the affordable market landscape.

Quality Assurance Steps

What are the key methods for making certain rigorous high quality control actions in the world of in-mold decors? Quality control actions are critical in in-mold decor processes to make certain the manufacturing of perfect and premium ended up items. One important technique is the execution of rigorous inspection procedures at every phase of the production procedure. This entails carrying out thorough visual assessments, dimensional checks, and color uniformity evaluations to determine any type of incongruities or defects beforehand.

Using innovative technologies such as computerized inspection systems can additionally enhance the quality assurance process by supplying trustworthy and exact information for evaluation. These systems can find flaws that might be missed out on by hands-on evaluations, therefore boosting general product top quality and uniformity.

Normal training and advancement programs for employees involved in the in-mold design procedure can also add to maintaining top notch requirements. By educating personnel on best techniques, top quality assumptions, and the relevance of interest to detail, firms can foster a society of top quality consciousness throughout the organization.

Consumer Appeal

To boost the bankability of in-mold decor items, comprehending and catering to customer preferences play a crucial role in identifying their allure and success. Offering modification alternatives such as individualized layouts, color variants, and textural elements can considerably enhance the appeal of in-mold design items.

Verdict

In-mold decors offer a functional and reliable way to boost product visual appeals. Grasping in-mold decors requires an all natural strategy that thinks about all elements of the production process to ensure success.

In the world of manufacturing, the art of in-mold decors stands as a critical element of product layout and production. Design innovation plays a vital duty in boosting the aesthetic charm, capability, and overall quality of items made utilizing in-mold decor procedures.One of the key elements of layout development in in-mold decors is the combination of detailed patterns, structures, and graphics that were formerly challenging to attain with typical design techniques.Effective manufacturing procedures are vital for equating the ingenious styles created in the field of in-mold decors right into high-grade ended up items that fulfill market demands and consumer expectations. Offering modification alternatives such as individualized styles, shade variants, and textural components can substantially enhance the charm of in-mold design products.

Report this page